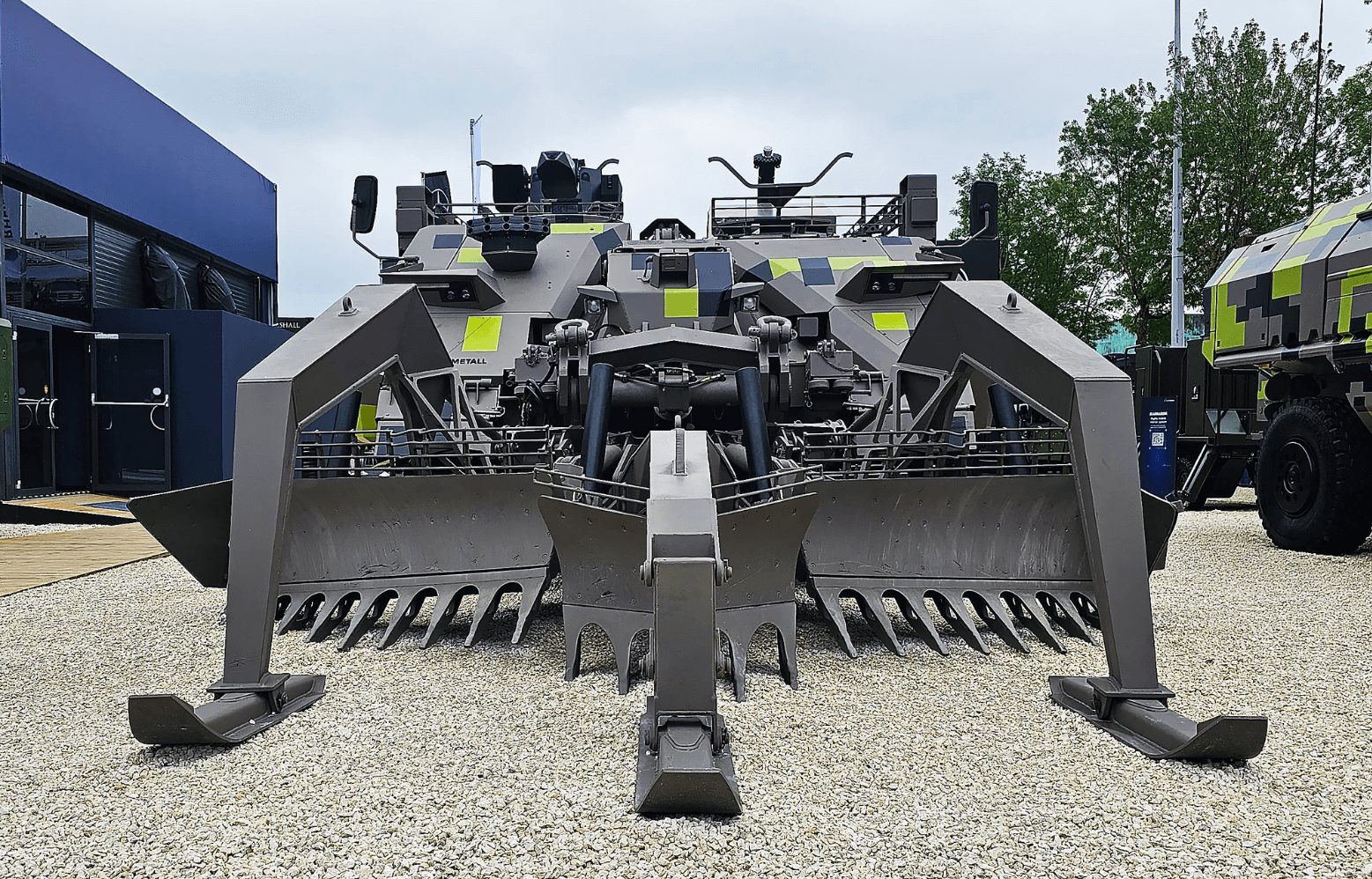

Pearson Engineering’s Route Opening Mine Plough was prominently displayed on FFG’s WiSENT 2, a versatile platform for engineering, mine clearance, recovery and bridge-laying operations.

For many years, Pearson Engineering and FFG have collaborated on a number of contracts to supply combat engineering equipment to armed forces across Europe, including most recently on the supply mine ploughs to Ukraine.

An initial contract was announced in January 2023 with a follow-on contract awarded in May 2024 for an additional undisclosed number of mine ploughs for several NATO nations.

Learn more on FFG and Pearson Engineering’s collaboration to supply Mine Plough UORs to Ukraine

Displaying a catalogue of land vehicles on their impressive stand at Eurosatory, Rheinmetall also featured Pearson Engineering’s Route Opening Mine Plough along with a Lane Marking System and Magnetic Signature Duplicator on their AEV3 KODIAK.

AEV3 KODIAK is Rheinmetall’s third generation of armoured engineer vehicle offering army engineers a robust, reliable and future-proof engineering vehicle with state-of-the-art equipment and high levels of protection and mobility. The concept platform combines modern engineering technology with tried and tested components from the iconic Leopard 2 battle tank.

More than 3,000 Pearson Engineering’s Mine Plough variations (Route Opening Mine Plough, Self-Protection Mine Plough, VECTOR and so forth) have been delivered to end-users across five continents to integrate on a wide range of combat vehicles.

“It was a pleasure to collaborate with our partners at Milrem, Rheinmetall and FFG during Eurosatory. Collectively, we demonstrated the value of tried, tested and proven equipment to meet the requirements of today, as well as to anticipate the needs of tomorrow’s fight. Together with the equipment displayed on our booth, I believe Pearson Engineering has demonstrated its ability to support end-users now and to anticipate the future of combat engineering. We’d like to extend our many thanks to all who visited us throughout the event.”

Richard Beatson – Business Development Director at Pearson Engineering

Our battle proven minefield breaching products provide armoured vehicles with the capability to defeat anti-tank mines. Whether intended for deliberate breaching or to support ‘freedom of manoeuvre’ for fighting vehicles, our blast-resistant ploughs give Commanders the option to move unimpeded and in doing so, maintain a battlefield advantage.

Our earth loading capability delivers a powerful digging and carrying ability, enabling armoured vehicles to transport materials, clear obstacles, dig and fill trenches and to assist in construction tasks. Our loaders can be provided with varying degrees of function and therefore complexity to support different mission sets.

Our interrogation capability is rooted in providing additional capability for Counter-IED and Route Proving operations. To supplement physical detection from ground engaging roller systems, our interrogation arm can be used to further understand the nature of threats and to identify where risks may be present outside of the path of the roller.

Our obstacle and earth moving products include general purpose and multi-purpose dozer blades, designed specifically to meet the needs of different mission sets. Our blades are designed to be tough, robust and lightweight, enabling a wide range of obstacle and earth moving activities whilst minimising the impact on the vehicle’s mobility.

Typically used alongside Pearson Engineering’s Route Opening Mine Plough, Surface Clearance Device or Route Proving rollers, our highly configurable obstacle marking systems support battlefield mobility by quickly and reliably marking safe lanes and the edge of hazardous areas.

Our excavation capability is designed to support combat engineer operations such as digging, demolishing, removing obstacles and filling trenches to support Area Access and Area Denial.

Our approach is often described as a ‘Swiss Army Knife’ in that host vehicles can be adapted to take on various combat engineering roles, or to overcome challenges to mobility. Integration of our products with the vehicle is made via a Pearson Engineering Direct Fit Interface or Pearson Engineering Quick Connect. The most suitable integration method depends on the mission requirements and vehicle capabilities. Our engineers will work closely with end-users and vehicle manufacturers to define the most appropriate route to minimise the impact on the vehicle and to maximise operational capability. Decisions are often based on hydraulic and electrical availability as well as the required role of the vehicle. Our integration kits are used to fit products that are designed to enhance armoured vehicle agility, tactical flexibility and adaptability. They are designed to be configurable and to deliver ‘freedom of manoeuvre’ to operations.

Our recovery capability includes a range of dedicated and multi-purpose blades which are primarily designed to support the recovery of other vehicles and for moving of heavy obstacles. A powerful ground-engaging blade sinks into the earth to hold a vehicle static, acting as the force against which the obstacle can be pulled. The same blade can be articulated to provide some obstacle and earth moving capability.

Surface laid mines represent a rising threat as Armed Forces turn their attention to near peer conflict. Our solutions, each designed to support the missions of dedicated combat engineer vehicles or fighting vehicles, provide a comprehensive detect and displace capability to support deliberate clearance or self-extraction in the face of air delivered scatterable mines.

Our highly configurable rollers have saved countless lives, limbs and assets on operations in Iraq and Afghanistan and have succeeded in ensuring ‘freedom of manoeuvre’ for soldiers around the world. Provided as either a full-width ‘route proving’ variant to actively check routes for the presence of Improvised Explosive Devices, or as a track-width ‘self-protection’ variant, our rollers are designed specifically to meet the needs of wide-ranging operational requirements. Our continued Research & Development and our approach to customisation provides confidence to those who use them.

Like all of Pearson Engineering’s products, our assault gap crossing solutions are designed to be modular, to be interchangeable with other mobility and counter-mobility equipment and to support ‘freedom of manoeuvre’ on the battlefield. In a time when units are tasked to ‘march divided and fight united’, independent manoeuvre support is key.

Our range of Mine Clearance platforms and tools provide Armed Forces and other organisations with scalable solutions for mine clearance, explosive ordnance disposal and the defeat of improvised explosive devices. Our platforms and their tools can also be used to create mobility challenges for adversaries. Proven around the world, these mine clearance platforms and their tools are designed specifically to meet the needs of different operational contexts from large area clearance to support logistics and peace keeping operations through to clearance in complex terrain.