about us

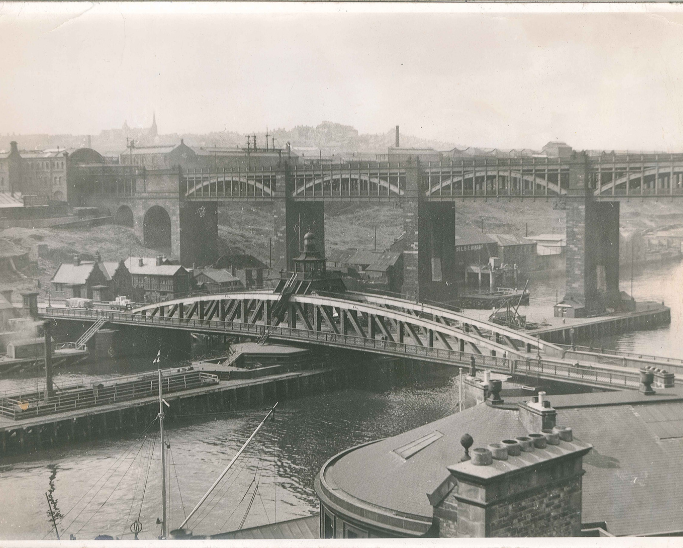

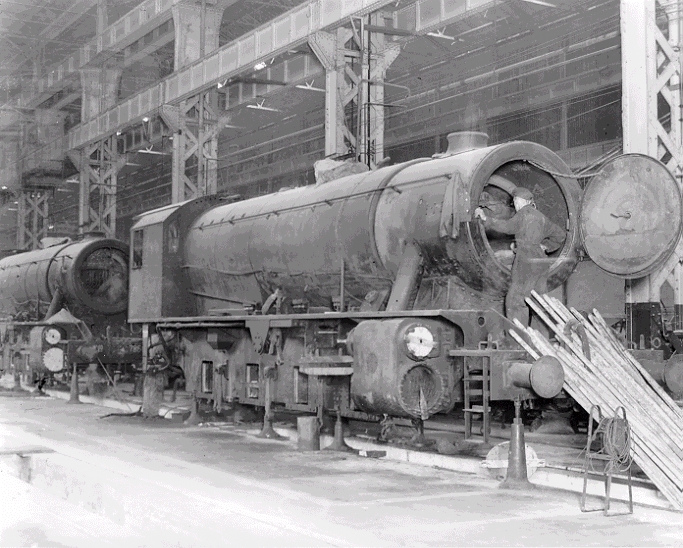

For more than four decades, Pearson Engineering has been synonymous with innovation, precision and the protection of life. From our home at the historic Armstrong Works in Newcastle upon Tyne, we unite world-class design, engineering and manufacturing expertise to deliver trusted technology across defence and critical industries.

Following our integration with Responsive Engineering, we now bring together over 440 specialists under one roof, combining advanced fabrication, machining and assembly with cutting-edge research and design-for-manufacture capability.

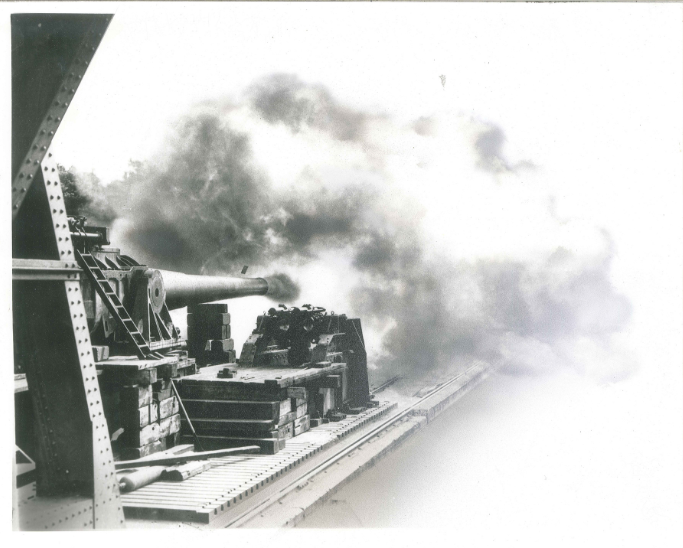

Our mission is simple: to help people, systems and nations move safely in a changing world. Whether developing battlefield technologies that protect soldiers or manufacturing components for civil infrastructure, we are engineering a safer tomorrow, together, through innovation, collaboration and excellence.

Engineering a safer tomorrow, together.

our company

Our reputation is built on engineering excellence and trust.

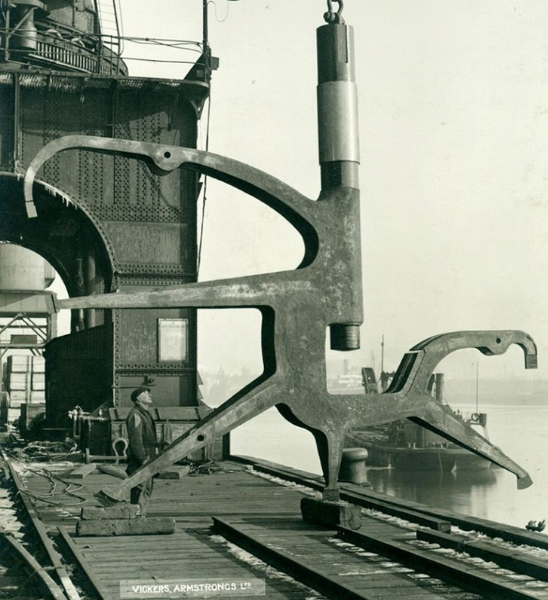

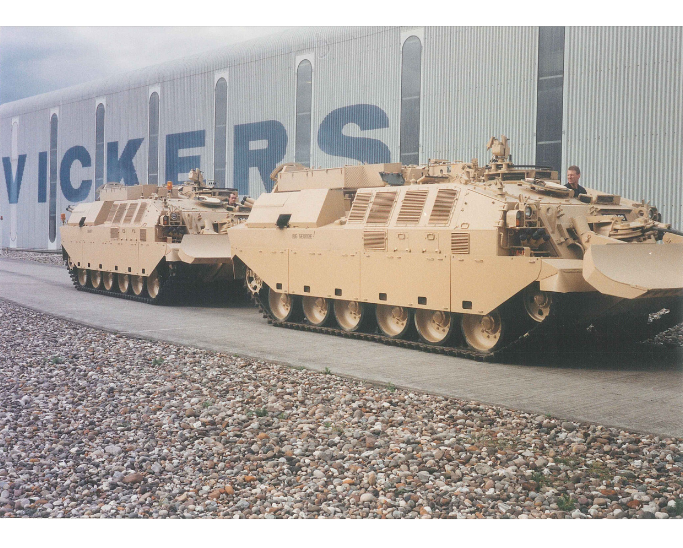

From our base at the Armstrong Works in Newcastle upon Tyne, we deliver complex, mission-critical solutions for both the defence and critical infrastructure sectors. Our highly skilled workforce provide expertise across design, fabrication, machining, and assembly – offering true end-to-end, build-to-print capabilities under one secure roof. This means total accountability, seamless delivery, and the assurance that every component we produce meets the highest possible standards.

We contribute to all major UK armoured vehicle programmes, including BOXER, Challenger 3 and AJAX, and extend our expertise to naval, rail, energy, and nuclear industries. Our processes combine advanced manufacturing technologies with expert design-for-manufacture insight, enabling faster turnaround, enhanced quality and security, and precision you can prove decades later.

Pearson Engineering is certified to DIN 2303 Q3, ISO 9001, ISO 3834, ISO 45001, ISO 14001, BS EN 1090, EN 15085 and JOSCAR.

These credentials demonstrate our commitment to the highest standards of quality, safety, and environmental performance, ensuring excellence and compliance across all operations.

Driven by a continuous cycle of strategic investment and pioneering innovation, we remain at the forefront of British engineering excellence.

In every project we undertake, no matter the scale or sector, our purpose remains the same: to design, develop, and manufacture advanced technologies that safeguard lives, empower communities, and strengthen the industries that drive our nation forward.

engineering a safer tomorrow, together.

Our Values

Our history

Latest news - KEV TO HELP

Join our team

Be a part of the future of engineering. Browse our current roles.